Adapted Stove Knob

Overview

I had the opportunity to take a 7-week course about Assistive Technology, where I was able to work with peers to design and develop customized AT for our disabled guest lecturers.Timeline: February 2023 - March 2023

Project Type: Assistive Technology Design

Role: UX Researcher & Designer (group member of 4)

Group members: Anzhelika Natashchuk, Mega Olonbayar, Sissi Zheng

![]()

![]()

Project Type: Assistive Technology Design

Role: UX Researcher & Designer (group member of 4)

Group members: Anzhelika Natashchuk, Mega Olonbayar, Sissi Zheng

Meet Andy

Andy loved to cook before his wrist became immobile from Acute Motor Axonal Neuropathy (AMAN). To help Andy take his first step back to cooking again, our team wanted to create an adapted stove knob handle tailored to his needs.The Problem

The main challenge for Andy was simultaneously:- gripping the handle,

- pushing the knob inwards,

- and rotating it.

Process

Research

We weren't able to find many existing AT for stove knobs, but the ones that were available online all required some sort of wrist turning and strength. The main areas they tackled seemed to be increasing the grip size so that the whole hand can be used instead of just the fingers, or extending the reach of the stove knobs for those positioned in the back area, as shown below.Cons:

- Requires wrist strength & rotating ability

- May cause balance issues (pressure point on the top instead of the center)

- Requires gripping ability

Ideation

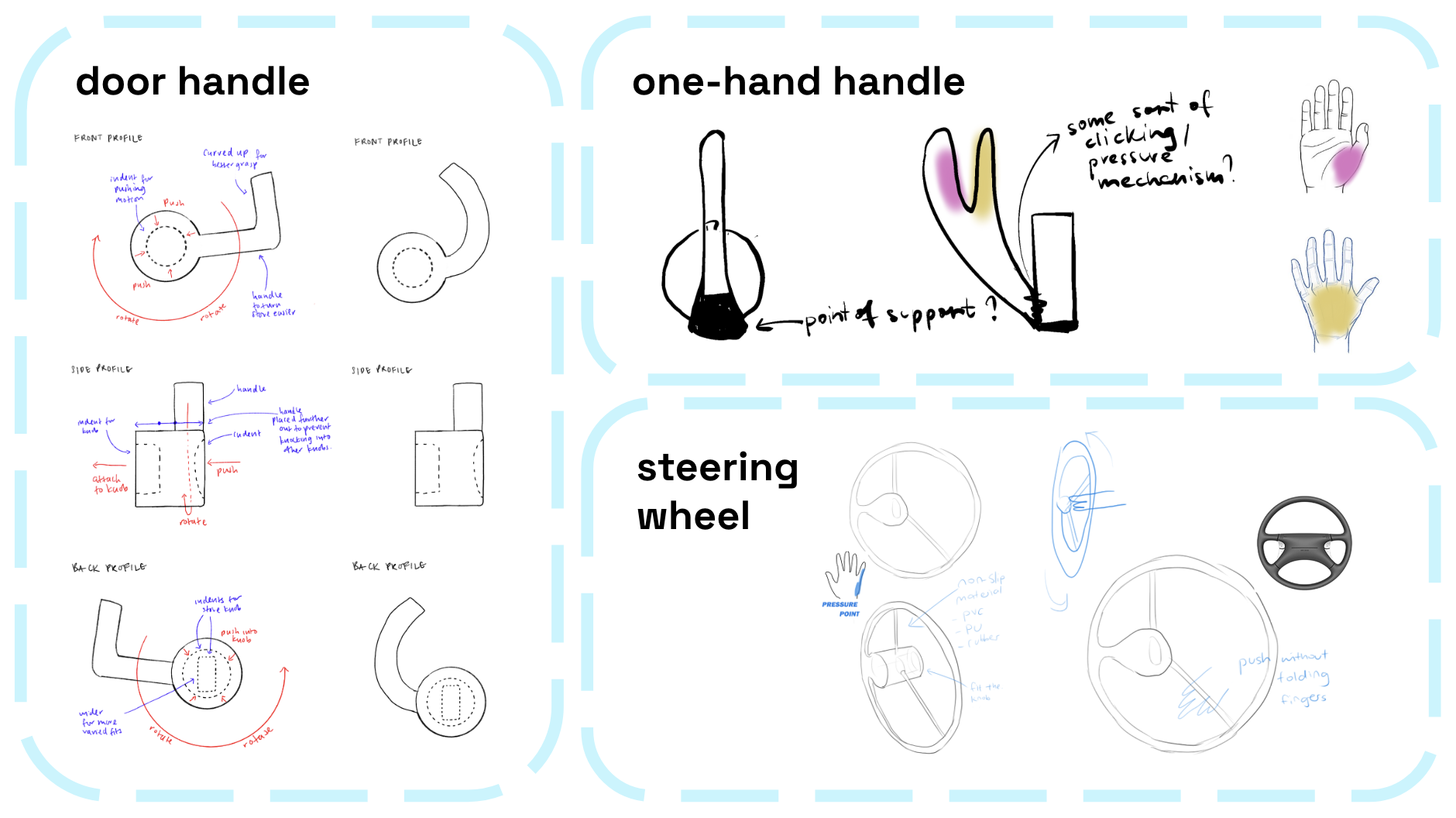

We all did our sketches individually, uploaded them to Miro to review, and met on Zoom to discuss our ideas. We provided feedback to each other, asking questions along the way to ensure that issues were addressed or recognized before we took any further action. We took inspiration from the problems found in existing AT and looked at how we could use handles from everyday life, like door handles and steering wheels.

Prototyping - Moldable Plastic

We started prototyping with the WhiteMorph moldable plastic to bring our sketches to life. We chose this medium because it was fast-drying and easy to reshape.After creating each mold, we tested it on the stove knob to see if it was easy to use, mimicking Andy's condition to better understand how he might use it himself.

During our testing, we asked the questions:

- How much force is required?

- What are the movements involved?

- How stable is the attachment?

- Does the adapted knob interfere with other knobs?

- Is the degree of rotation less than 90°?

This evaluation helped us to refine our designs and was critical to helping us eliminate a few designs, correcting our design assumptions.

Prototyping - 3D Printing

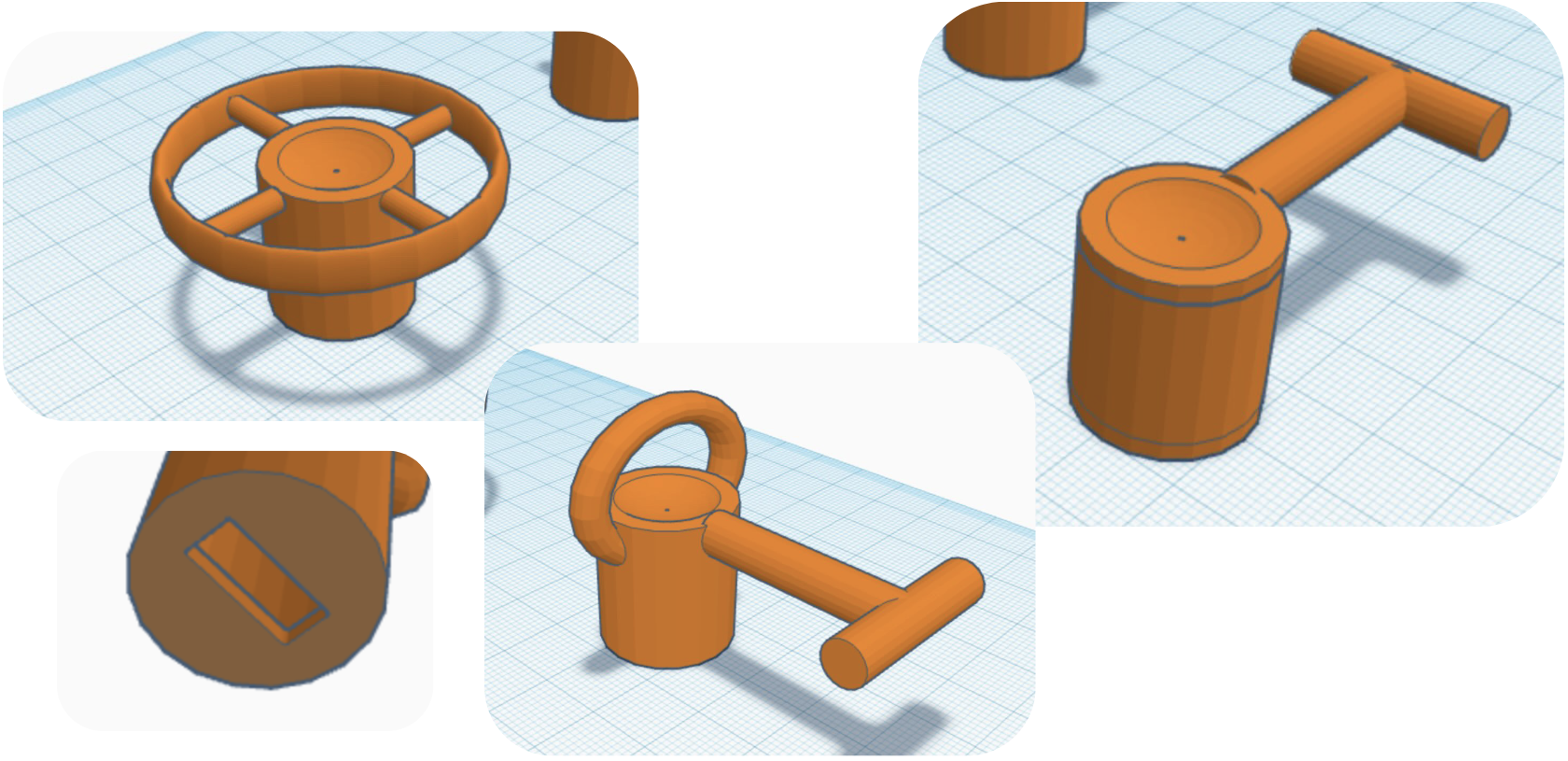

After trying out the moldable plastic, we felt that the products didn't seem super smooth or aesthetically pleasing for everyday use. They were also a little heavy. 3D-printed products, on the other hand, would help to make the product look cleaner and reduce its weight. During this stage of the process, a groupmate and I took on the role of 3D modeling on TinkerCad, while the others went to the NYU MakerSpace to print out a model. We modeled four different adapted stove knob handles to scale, but due to time and material constraints, we could only choose one to print, which was decided based on a reflection and discussion regarding our testing insights.

Based on testing, we decided to print the T-shaped door handle design due to its ability to effectively separate the motions of pushing and turning, as well as accommodate stove knobs that turn in different directions.

Once we finished printing our final design, we found that the sizing wasn't exactly correct and that the base bath didn’t go smoothly (hence the rough bits sticking on). So, we used a knife to scrape it down, making it better fit the knob handle we had. We made the TinkerCAD models easily adjustable to accommodate other stove knob sizes.

Final Demos

We found that while testing, each of us used the prototypes differently, so below are two different ways of using our final product.Limitations & Concerns

- Because there is no adhesive/grip at the point where it attaches to the stove knob handle, holding it up to the knob might be an issue.

- Stove knobs differ in size and shape, so we hope this can work for Andy's kitchen. The online designs are easily adjustable, so it is okay if the one we print doesn't work out.

- We couldn't do user testing directly with Andy during the design process, so we weren't 100% sure that this was the best design for him. However, he was able to take all of the prototypes we made for him, including the plastic prototypes.

Reflection

- We learned new techniques and how to use unfamiliar materials and software.

- Limited time frame and costs may have constrained our user testing processes.

- In an ideal world, we would create a set of cooking tools for Andy so that he can turn on the stove and flip his eggs.

After presenting to the class, and Andy, he took home all of the prototypes, including the moldable plastic ones.